Glycerol Monostearate: A Comprehensive Overview for the Chemical Industry

Introduction

Glycerol monostearate is a widely utilized chemical compound in various industrial applications, particularly within the food, pharmaceutical, and cosmetic sectors. As a monoglyceride derived from glycerol and stearic acid, it functions primarily as an emulsifier, stabilizer, and thickening agent. Its unique properties make it an indispensable ingredient in many formulations. This article provides a detailed examination of glycerol monostearate, focusing on its chemical nature, composition, applications, and storage requirements, with an emphasis on its relevance in the chemical industry.

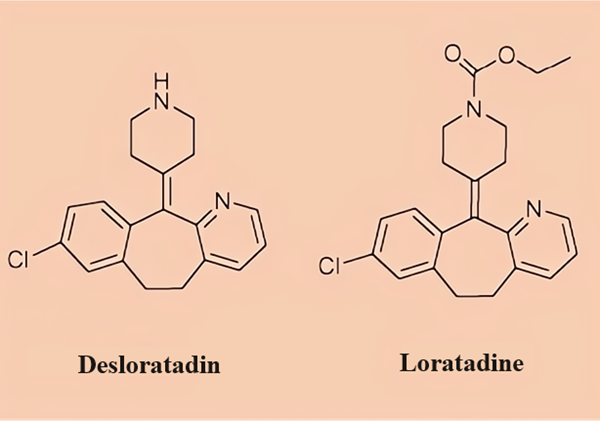

Figure 1 Characteristics of Glycerol monostearate

Properties of Glycerol Monostearate

Glycerol monostearate has the chemical formula C21H42O4. It is a white, odorless, and sweet-tasting flaky powder, solid at room temperature. The molecular structure of GLYCEROL MONOSTEARATE consists of a glycerol backbone attached to a single fatty acid chain—stearic acid—via an ester bond. This amphiphilic structure, with both hydrophilic and lipophilic regions, enables it to act as an effective emulsifying agent.

GLYCEROL MONOSTEARATE exhibits a melting point range of 57–65°C, which varies depending on its purity and the ratio of mono-, di-, and triglycerides present in the mixture. It is insoluble in water but dispersible, allowing it to form stable emulsions when combined with water and oil phases. Additionally, GLYCEROL MONOSTEARATE is soluble in alcohols and organic solvents such as ethanol and acetone.

The emulsification capacity of glycerol monostearate is largely due to its ability to reduce the surface tension between immiscible liquids, such as oil and water. This property is crucial in food processing, where it helps create homogenous mixtures and improves the texture and shelf life of products. Moreover, GLYCEROL MONOSTEARATE also exhibits hygroscopic properties, meaning it can attract and retain moisture, which is beneficial in various applications requiring moisture control.

Composition and Main Constituents

Glycerol monostearate is typically produced through the esterification of glycerol with stearic acid, which can be derived from both animal and vegetable fats. The resulting product is not purely monostearate but a mixture of mono-, di-, and triglycerides. The concentration of the monoglyceride in commercial GLYCEROL MONOSTEARATE typically ranges from 40% to 60%, with the remainder being di- and triglycerides, free glycerol, and unreacted fatty acids.

The ratio of these constituents can vary depending on the production method and the desired application. For example, in food-grade GLYCEROL MONOSTEARATE, a higher concentration of monoglycerides is often preferred to enhance emulsifying properties. Conversely, technical-grade GLYCEROL MONOSTEARATE used in industrial applications may have a different composition tailored to specific functional requirements.

The fatty acid composition of GLYCEROL MONOSTEARATE is also a key factor in its properties and applications. While stearic acid is the primary fatty acid in GLYCEROL MONOSTEARATE, other saturated fatty acids like palmitic acid may also be present. These variations can influence the melting point, emulsification capacity, and overall performance of the product.

Applications of Glycerol Monostearate

Glycerol monostearate's versatility is reflected in its wide range of applications across multiple industries. Its primary function as an emulsifier makes it indispensable in the production of various consumer goods.

Food Industry:

In the food industry, GLYCEROL MONOSTEARATE is extensively used as an emulsifier and stabilizer in products like margarine, shortening, ice cream, whipped cream, and bakery goods. It helps improve the consistency and texture of these products, prevents separation of ingredients, and extends shelf life. In ice cream, for example, GLYCEROL MONOSTEARATE aids in controlling the formation of ice crystals, resulting in a smoother texture. In bread making, it enhances dough strength and elasticity, leading to improved volume and crumb structure.

Pharmaceutical Industry:

In the pharmaceutical sector, GLYCEROL MONOSTEARATE serves as an excipient in the formulation of tablets, capsules, and creams. Its emulsifying properties ensure the uniform distribution of active ingredients in creams and ointments, while its ability to act as a lubricant and release agent in tablet manufacturing enhances the ease of production and quality of the final product. Moreover, GLYCEROL MONOSTEARATE is also used in controlled-release formulations, where it helps modulate the release rate of active pharmaceutical ingredients.

Cosmetic Industry:

In cosmetics, glycerol monostearate is a common ingredient in lotions, creams, and makeup products. It acts as an emulsifier to combine oil and water phases, creating stable and homogenous products. GLYCEROL MONOSTEARATE also imparts a smooth, creamy texture to lotions and creams, enhancing their spreadability and skin feel. Additionally, its moisture-retaining properties help maintain skin hydration, making it a valuable ingredient in skincare products.

Industrial Applications:

Beyond consumer products, GLYCEROL MONOSTEARATE is used in various industrial applications, including the production of plastics, where it acts as an anti-static agent and a lubricant in the processing of polymers. In the textile industry, GLYCEROL MONOSTEARATE is utilized as a softening agent, imparting a smooth and flexible finish to fabrics. Furthermore, it finds use in the production of rubber and other synthetic materials, where it enhances processing efficiency and product quality.

Storage and Handling of Glycerol Monostearate

Proper storage and handling of glycerol monostearate are crucial to maintaining its quality and functionality. GLYCEROL MONOSTEARATE should be stored in a cool, dry place, away from direct sunlight and moisture. Exposure to high temperatures can cause the product to melt and clump, affecting its emulsifying properties. Similarly, exposure to moisture can lead to hydrolysis, resulting in the breakdown of the ester bond and the formation of free fatty acids and glycerol, which can negatively impact the product's performance.

To prevent contamination, GLYCEROL MONOSTEARATE should be stored in airtight containers, preferably made of materials resistant to moisture and oxygen penetration. In industrial settings, it is advisable to store GLYCEROL MONOSTEARATE in bulk silos or large bags with proper sealing to protect it from environmental factors. During handling, personnel should use appropriate protective equipment, such as gloves and masks, to avoid direct contact and inhalation of dust particles.

![Article illustration]() Reference

Reference

[1] Han L, Wang T. Preparation of glycerol monostearate from glycerol carbonate and stearic acid[J]. RSC Advances, 2016, 6(41): 34137-34145.

[2] Yu C C, Lee Y S, Cheon B S, et al. Synthesis of glycerol monostearate with high purity[J]. Bulletin-Korean Chemical Society, 2003, 24(8): 1229-1231.

);Lastest Price from Glyceryl monostearate manufacturers

US $8.70/kg2024-09-19

- CAS:

- 31566-31-1

- Min. Order:

- 10kg

- Purity:

- 99.5% min

- Supply Ability:

- 10000kg

US $0.00/KG2024-09-18

- CAS:

- 31566-31-1

- Min. Order:

- 1KG

- Purity:

- 98%min

- Supply Ability:

- 30tons/month