Chromium——Sources of Exposure & Risk Assessments

First aid: Seek medical assistance immediately as effects may be severe or life threatening. Oral exposure: Do not induce vomiting, seek medical assistance. Eye exposure: Remove from exposure, remove contact lenses, flush with water, see ophthalmologist. Inhalation exposure: Remove from exposure, ensure adequate ventilation, oxygen if symptomatic, seek medical assistance. Dermal exposure: Remove from exposure, flush with water, seek medical assistance.

Target organs: Inhalation exposure: Respiratory tract. Dermal exposure: Skin, mucous membranes.

Occupational exposure limits (OELs): Specific Cr(VI) compounds may have distinct OELs.

OSHA: 5 μg/m3 8 h time-weighted average (TWA).

NIOSH: 0.2 μg/m3 8 h TWA.

ACGIH: 50 μg/m3 water-soluble 8 h TWA.

10 μg/m3 insoluble 8 h TWA.

SOURCES OF EXPOSURE

Occupational

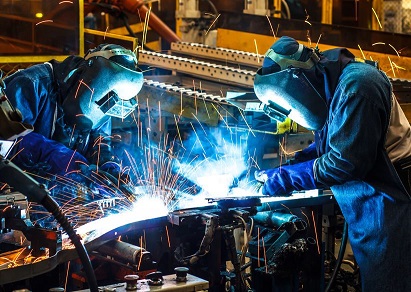

Workers may be exposed to airborne Cr(VI) when Cr(VI) compounds are manufactured from other forms of chromium (e.g., production of chromates from chromite ore); when using Cr(VI)-containing materials to manufacture other products (e.g., chromate-containing paints, electroplating); or when Cr(VI) is produced as a by-product of a process (e.g., welding). Primary industries with the majority of occupational exposures to airborne Cr(VI) compounds include welding, painting, electroplating, steel mills, iron and steel foundries, wood preserving, paint and coatings production, chromium catalyst production, plastic colorant producers and users, production of chromates and related chemicals from chromite ore, plating mixture production, printing ink producers, chromium metal production, chromate pigment production, and chromated copper arsenate producers (71 Fed. Reg. 10099, 2006).

Welders are the largest group of workers potentially exposed to Cr(VI) compounds (71 Fed. Reg. 10099, 2006).

Cr(VI) exposures to welders are dependent on several process factors, including the welding process and shield-gas type, and the Cr content of both the consumable material and the base metal (Keane et al., 2009; Meeker et al., 2010). Other industrial sectors with substantial numbers of workers exposed include painting, electroplating, steel mills, and iron and steel foundries (71 Fed. Reg. 10099, 2006).

Blade et al. (2007) conducted a series of field surveys of workplaces where there was a potential for Cr(VI) exposure. The authors reported that controlling airborne Cr(VI) exposures was moderately difficult in those operations that involved joining or cutting metals with a relatively high chromium content. Airborne Cr(VI) exposures were reported most difficult to control in those operations involving the application of coatings or finishes.

Dermal exposure to Cr(VI)-containing substances may occur with any task where there is a potential for splashing, spilling, or other skin contact. If not adequately protected, workers’ skin may be directly exposed to liquid forms of Cr(VI) (e.g., electroplating baths) or solid forms (e.g., Portland cement). A variety of construction materials contain Portland cement, including cement, mortar, stucco, and terrazzo (OSHA, 2008). Dermal exposure may also occur because of contamination of workplace surfaces or equipment.

Environmental

Chromium(VI) compounds are released to the air, water, and soil from natural and industrial sources. Cr(VI) levels are usually low in U.S. ambient air, <30 ng/m3 (ATSDR, 2012). Chromium in the air is eventually deposited on to the soil and water. Environmental conditions in the soil and water, (e.g., pH), affect the state of chromium, potential exposures, and toxicity. Cr(VI) compounds may be present in surface waters or groundwater. Potential exposures to Cr(VI) may occur from the ingestion of drinking water or the inhalation of water droplets when showering (OEHHA, 2009).

The control measures for Cr(VI) compounds, consistent with the hierarchy of controls, include: elimination, substitution, engineering controls, administrative controls and appropriate work practices, and the use of protective clothing and equipment (NIOSH, 2013). Employers should provide gloves, chemical protective clothing (CPC), and eye protective equipment for workers with potential skin or eye contact with Cr(VI) compounds. Selection of CPC should be based on permeation properties and other factors, including size, dexterity, cut and tear resistance, and other chemicals being used. Dermal and mucous membrane contact should be prevented by full-body protective clothing, including head, neck, and face protection; coveralls or similar protective body clothing; impermeable gloves with gauntlets; and shoes and apron. When respiratory protection is needed to control workplace exposures, the employer should establish a comprehensive respiratory protection program as described in the OSHA respiratory protection standard (CFR, 2006 29 CFR 1910.134).

RISK ASSESSMENTS

Studies of chromate manufacturing workers in Baltimore, Maryland, and Painesville, Ohio provided exposure-response data for assessing the excess risk of lung cancer associated with occupational exposure to Cr(VI). These cohorts provided the basis for robust quantitative assessments of occupational risk of Cr(VI) exposure due to the quality and quantity of the exposure and worker data, extent of exposure, and years of follow-up.

Park et al. (2004) calculated excess lifetime risk of lung cancer death resulting from occupational exposure to chromiumcontaining mists and dusts using the data of Gibb et al.

(2000b), the Baltimore cohort of chromate chemical production workers. This cohort had extensive historical exposure assessment and smoking information, strong statistical power, and a relative lack of potentially confounding exposures. A linear relative rate model was selected to estimate the exposure response that was the basis for the risk assessment. The excess lifetime risk of lung cancer death was approximately 6 per 1000 workers from a 45-year working lifetime exposure to 1 μg/m3 soluble hexavalent chromium.

Crump et al. (2003) calculated estimates of excess lifetime risk of lung cancer death using the data of Luippold et al. (2003), the Painesville cohort of chromate chemical production workers. This cohort had an extensive exposure assessment (Proctor et al., 2003). The estimate of excess lifetime risk of lung cancer death was approximately 2 per 1000 workers from a 45-year working lifetime exposure to 1 μg/m3 hexavalent chromium.

The findings and conclusions in this report are those of the author and do not necessarily represent the views of the National Institute for Occupational Safety and Health.

REFERENCES

Gibb, H.J., Lees, P.S., Pinsky, P.F., and Rooney, B.C. (2000b) Lung cancer among workers in chromium chemical production. Am. J. Ind. Med. 38(2):115–126.

Glaser, U., Hochrainer, D., Kloppel, H., and Oldiges, H. (1986) Carcinogenicity of sodium dichromate and chromium (VI/III) oxide aerosols inhaled by male Wistar rats. Toxicology 42:219–232.

IARC (1990) IARC Monographs on the Evaluation of the Carcinogenic Risk of Chemicals to Man: Chromium, Nickel, and Welding, vol. 49, Lyon, France: World Health Organization, International Agency for Research on Cancer, pp. 49–256.

IARC (2012) IARC Monographs on the Evaluation of Carcinogenic Risks to Humans: Arsenic, Metals, Fibres, and Dusts, vol. 100C, Lyon, France: World Health Organization, International Agency for Research on Cancer, pp. 49–256.

You may like

Related articles And Qustion

See also

Lastest Price from Chromium manufacturers

US $10.00/KG2024-05-28

- CAS:

- 7440-47-3

- Min. Order:

- 100KG

- Purity:

- 99%

- Supply Ability:

- 100 mt

US $10.00/kg2024-03-08

- CAS:

- 7440-47-3

- Min. Order:

- 1kg

- Purity:

- 99%

- Supply Ability:

- 1000kg